Kremsmüller Test Center

Kremsmüller Test Center

Innovative solutions and customized processes in evaporation and drying technology

Focusing on energy efficiency and environmental friendliness, the Kremsmüller Test Center provides a top-tier platform for the development of sustainable solutions in various industries.

We utilize our expertise and advanced facilities to lend you our support in realizing your visions for an environmentally conscious future.

Kremsmüller Test Center

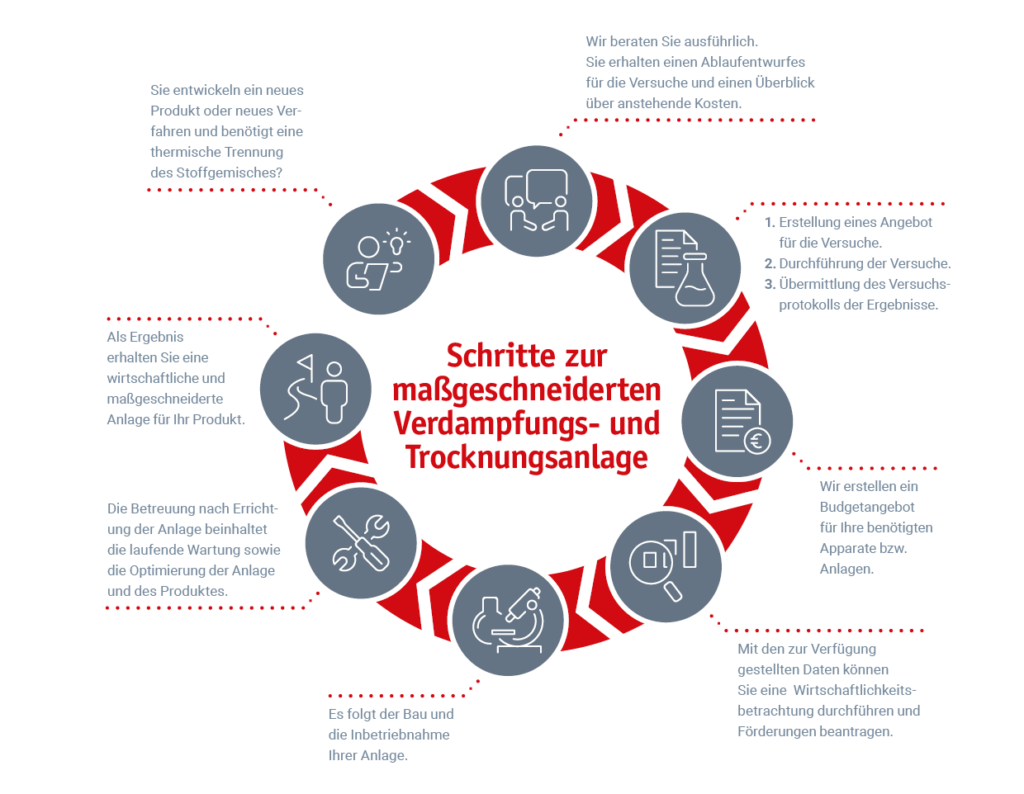

Enter into the engineering phase at no risk

Before you make large investments in a process plant or equipment, we test your products under the process parameters you specify. This allows you to form an overall perspective of your planned project and, thus, the best conditions for the start of the scale-up process. Consequently, you can initiate further project steps and engineering phases without transfer risk.

We go a crucial step further

We know that you as a customer attach vital importance to the economic efficiency and feasibility of your projects. This is exactly why we start focusing on these goals from the word “go”. We go above and beyond the services rendered by conventional research institutions. Our expertise in apparatus construction lets us factor in your future overall system as soon as we receive your initial request. Not only do we offer you key figures, consumption numbers and information on the theoretical feasibility, but we also analyse the economic aspects and the actual feasibility of your undertakings. The assistance we lend you will not only let you realise your project, but will also turn it into an economic success.

We always keep a firm eye on your overall system.

Kremsmüller Test Center

Process development tailored to your requirements

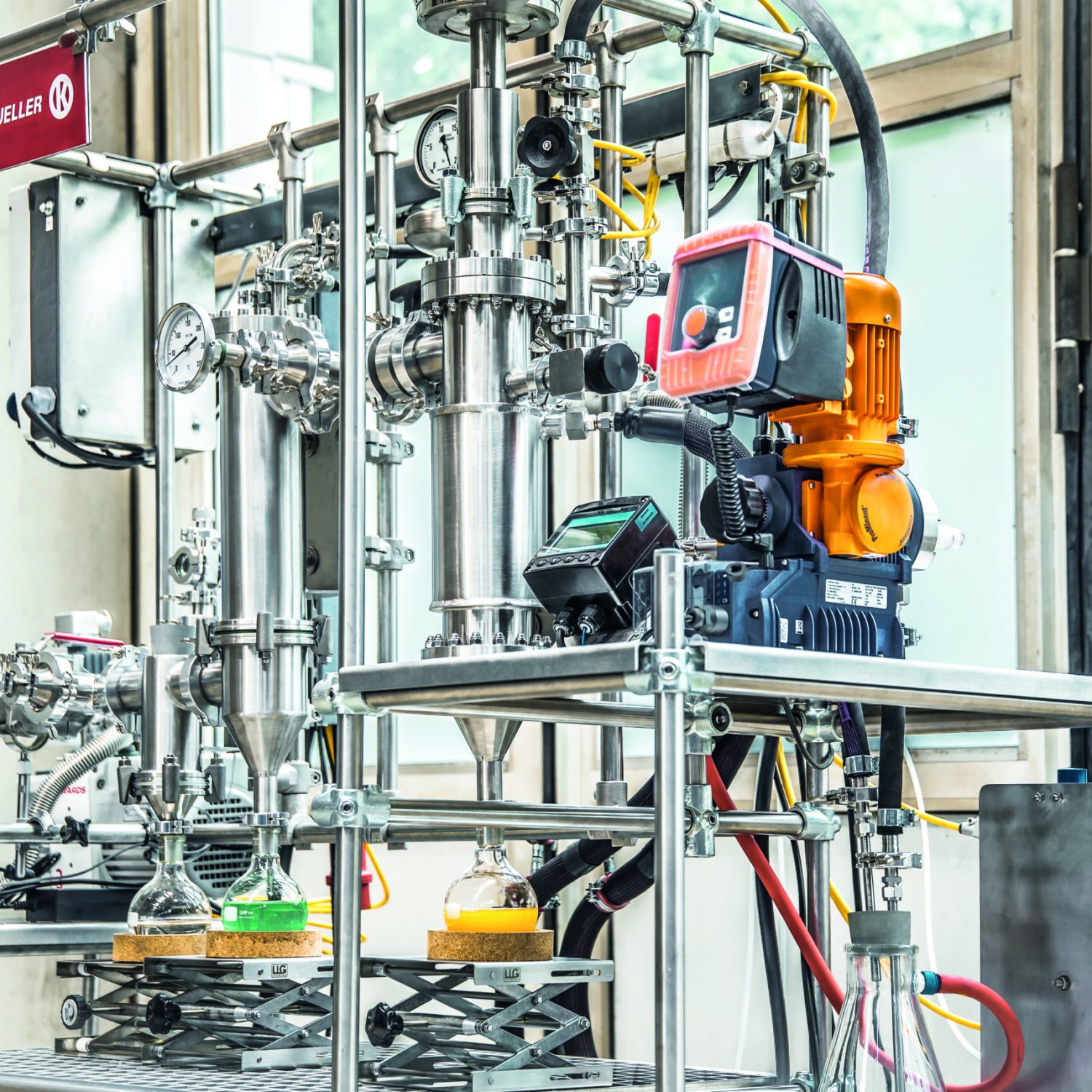

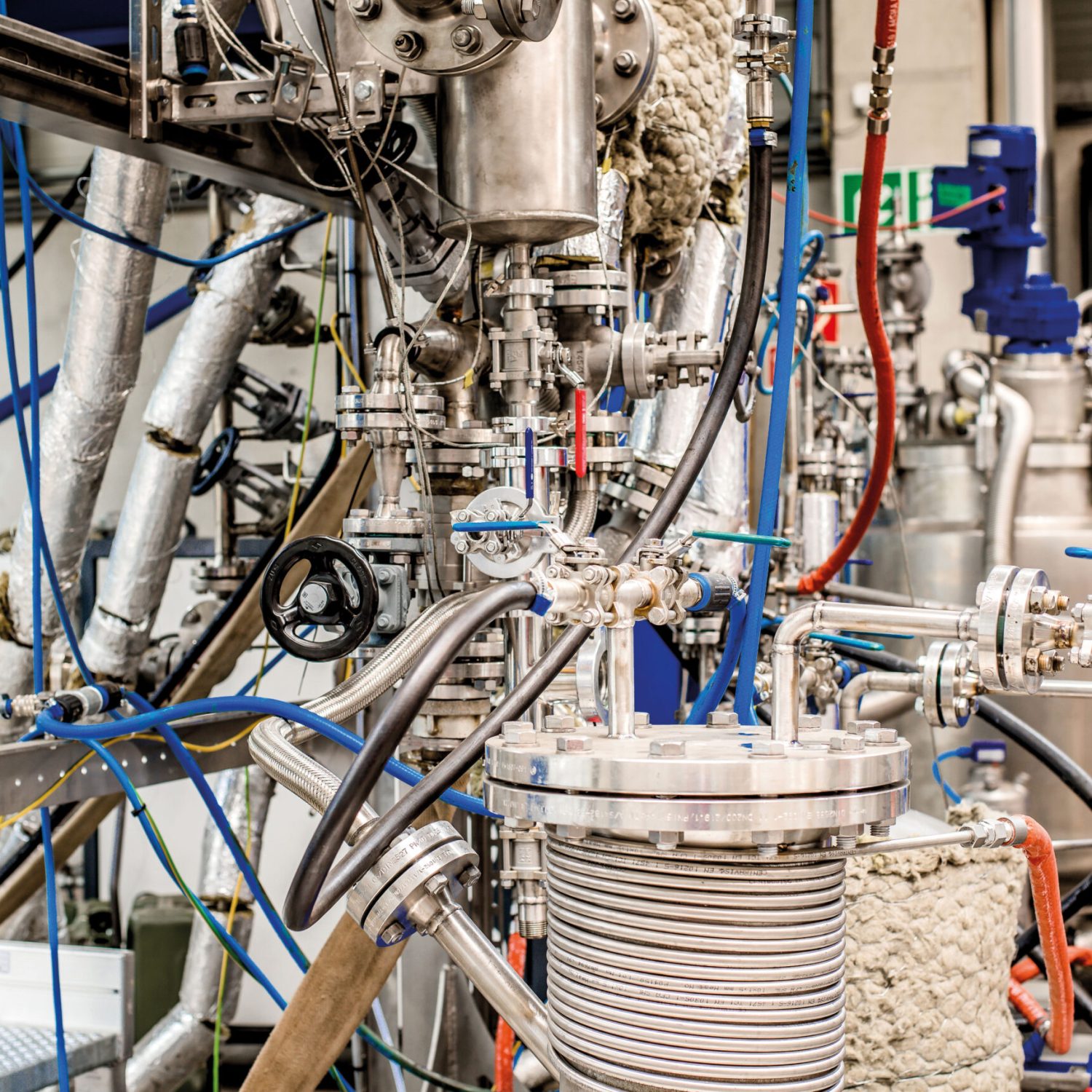

The technical center in Steinhaus near Wels is equipped with various evaporators and dryers, including all relevant process engineering components. This enables us to carry out a wide range of process developments and simulations directly on site. Quantities from a few grams up to 200 kg can be processed in our systems. The process conditions can be flexibly adapted.

Technologies (min. required product quantity)

- Thin film evaporator “LiquiVap” (>2kg)

- Falling film evaporator “LiquiFilm” (>20kg)

- Short path evaporator ‘LiquiMol’ (>2kg)

- Horizontal thin film dryer “LiquiDry” (>10kg)

Technical data:

- Up to 10^-3 mbar(a)

- Up to 350°C

Decision-making based on further analyses and feasibility studies

The results gathered from the field tests conducted at the technical centre open up numerous possibilities for further analyses and studies. The resulting findings make it possible to carry out feasibility studies in a bid to evaluate the feasibility of your projects. Mass and energy balances help you gain a comprehensive understanding of the process and identify potential increases in efficiency. Steps that help optimize the processes of procedural devices and systems already in place provide valuable results for the performance improvement of your plant. Material impact assessments support you in decision-making and provide you with quantitative statements about the planned charge material.

Ask our experts!

Kremsmüller Test Center

Complete range of chemical and physical process engineering

• Waste treatment

• Wastewater technology

• Sewage sludge technology

• Petrochemistry

• Food industry

• Plastics industry

• Fertilizer industry

• Representatives from the organic and

inorganic chemical sector

At the Kremsmüller Pilot Plant, we combine state-of-the-art facilities with the technical knowledge and expertise of our highly qualified employees. Rely on our experienced team to develop and implement tailor-made solutions and innovative approaches to meet the challenges of chemical and physical process engineering.