There’s Perfection in the Hidden Depths

Welding at temperatures familiar only in the sauna – remote heating professionals test the limits of physical endurance.

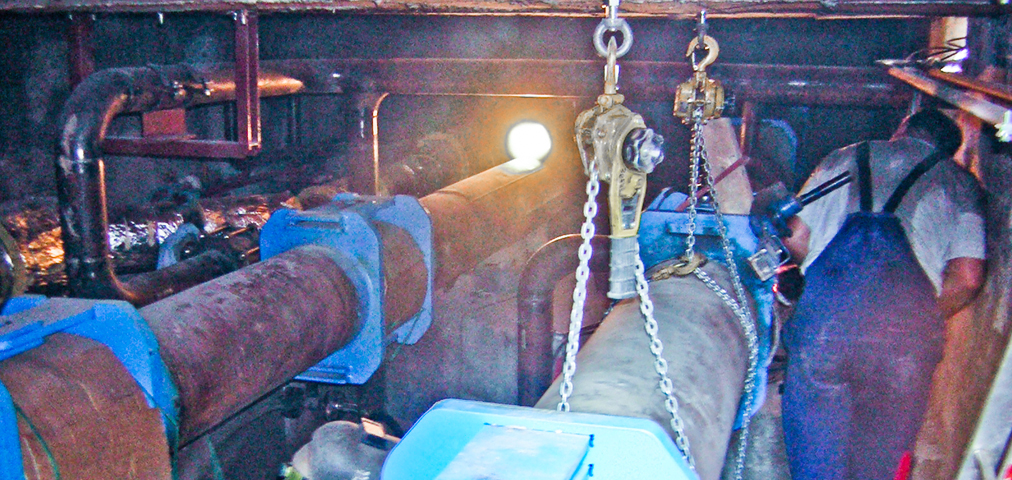

Kremsmueller stepped in among the supply machinery of a hospital on behalf of a remote heating supplier. Fitters replaced the compensators of the pipe. The temperature compensation elements had a diameter from 200 to 400 mm. A chain hoist was used to thread all the installation equipment through the angled shafts of the hospital.

The work posed the experts serious challenges: The men welded exact seams at 70 °C heat. A continuous supply of fresh air and exhausting of the welding smoke facilitated safe working. Enormous challenges, but they were not allowed to cause any wobble in the project schedule: A week before the scheduled completion, the work was finished to the complete satisfaction of the customer.

To guarantee continued supply of the remote heat to the hospital, one supply pipe with a forward and return line always had to be kept operational. Movements in the remote heating pipes – especially from vibrations or thermal elongation or contraction – are now once again optimally balanced out by the compensators.

The thermal energy consumption of the hospital is huge: the equivalent of 3,200 four-person households with a living area of 150 m².

Would you like to know more about the project? Click on the right on "Contact" to directly reach our experts.

You can get more information about District heating on wikipedia.en