Hops and malt, inspection sustains it all

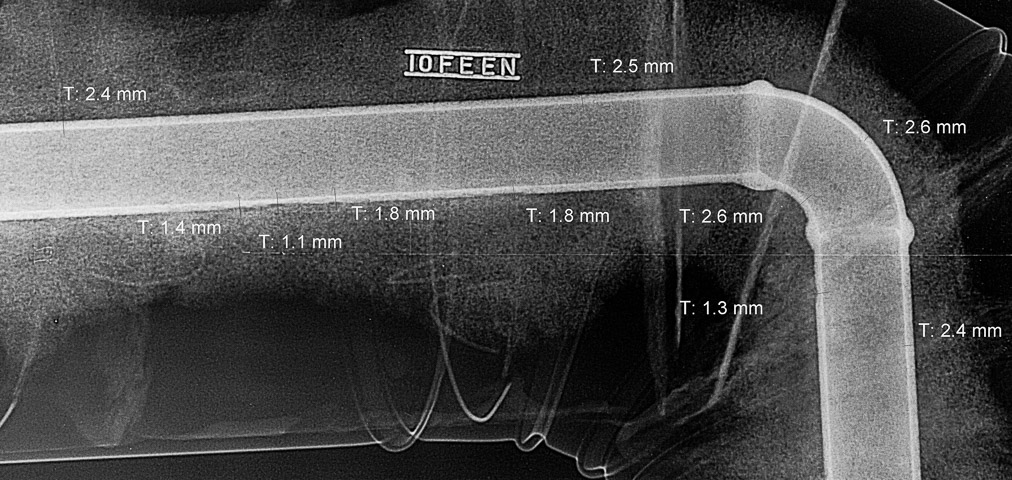

The condition of insulated pipes is inspected in Austrian breweries. This is made possible by computer radiography.

There exist temperature differences of up to 60 degrees Celsius between the pipes and the outer side of the insulation. This can lead to water agglomeration, which results in corrosion and in consequence, permanent damage to the pipes.

This was a case for the action team from materials testing. It was travelling all over Austria to inspect the condition of the ammonia pipes in breweries. Computer radiography was used for the purpose. Kremsmueller has employed this process for a few years now and is a leader in its use.

If you would like to know more about materials testing, please click on Contact (envelope icon). You will then be put directly in contact by email with our experts.

This was a case for the action team from materials testing. It was travelling all over Austria to inspect the condition of the ammonia pipes in breweries. Computer radiography was used for the purpose. Kremsmueller has employed this process for a few years now and is a leader in its use.

If you would like to know more about materials testing, please click on Contact (envelope icon). You will then be put directly in contact by email with our experts.