Large scale operation for burnt-down paper machine

The machine was re-commissioned after just 80 days. The pipeline construction and I&C divisions had a large part to play in the fast repairs.

Quick action was the need of the hour after a fire broke out in the Papierfabrik Laakirchen (Laakirchen Paper Factory) – to put it more precisely, on one of the paper machines in the press section. 14 fire engines with a total of 250 firefighters fought the flames, but nonetheless, the damage was serious. The expected downtime was put at half a year.

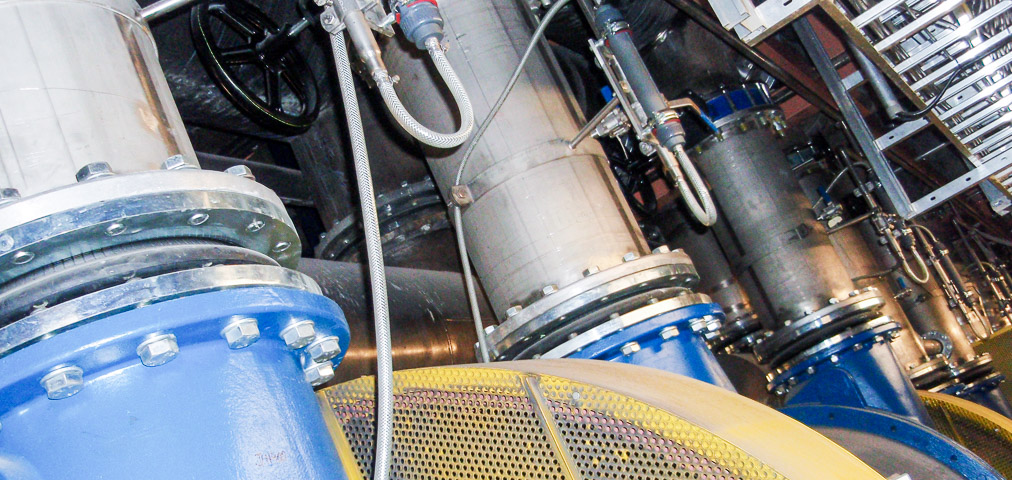

The order of magnitude of the total repairs: 70,000m² of production shed walls, the construction as well as all the machine parts and rollers had to be cleaned, 100km cables including the cable routes and 4km of hydraulic pipes had to be laid afresh. In addition, 30 running metres of new drive cubicles – as a proven and reliable partner, Kremsmueller was also tasked with this spontaneous major project.

“All the material orders had to be fulfilled in as short a time as possible, which also worked out well. We had a team of 60 deployed at the site and we worked in day and night shifts, simultaneously with other suppliers and partners. The customer’s coordination of all those involved in the repairs certainly contributed significantly to the speed of execution”, underlines department head Rudolf Raberger. And in fact, the burnt-out paper machine was recommissioned in just 80 days, twice as fast as originally planned.

Would you like more information on the project? Click on Contact and you will be put in touch with our experts by email.

The order of magnitude of the total repairs: 70,000m² of production shed walls, the construction as well as all the machine parts and rollers had to be cleaned, 100km cables including the cable routes and 4km of hydraulic pipes had to be laid afresh. In addition, 30 running metres of new drive cubicles – as a proven and reliable partner, Kremsmueller was also tasked with this spontaneous major project.

“All the material orders had to be fulfilled in as short a time as possible, which also worked out well. We had a team of 60 deployed at the site and we worked in day and night shifts, simultaneously with other suppliers and partners. The customer’s coordination of all those involved in the repairs certainly contributed significantly to the speed of execution”, underlines department head Rudolf Raberger. And in fact, the burnt-out paper machine was recommissioned in just 80 days, twice as fast as originally planned.

Would you like more information on the project? Click on Contact and you will be put in touch with our experts by email.