Bitumen cooling

Two completely finished cooling systems for bitumen

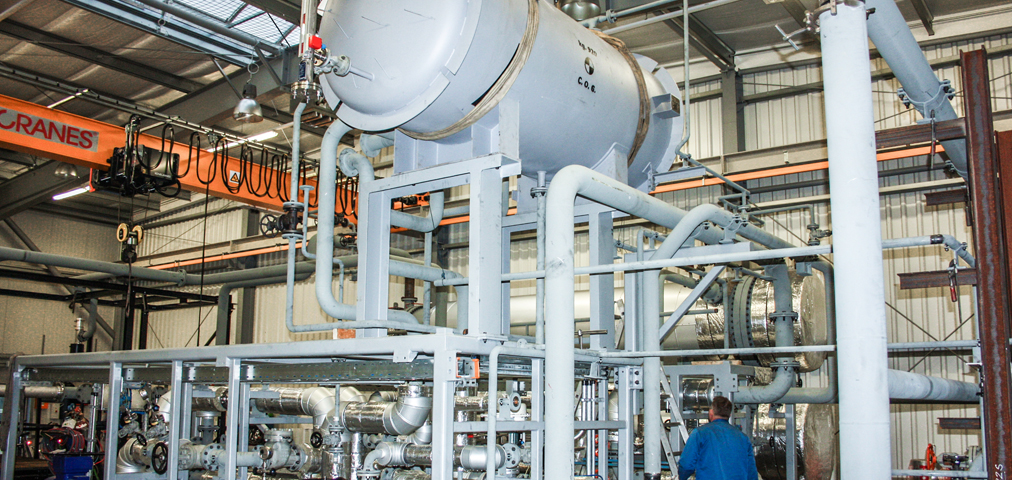

The customer had developed a sophisticated system to facilitate the filling of bitumen in BigBags. Since bitumen is normally stored in liquid state at temperatures between 160°C and 200°C, a special cooling system was required to be able to fill bitumen for the simple transport and storage. Which is where Kremsmueller came into the picture.

The plant construction experts of Kremsmueller fabricated two complete cooling plants for the crude oil byproduct. In this project, too, many competence domains of Kremsmueller meshed with one another: I&C, steel and pipe construction, as well as installation at the end-customer’s site.

Two plants were manufactured, with each weighing between 130 and 140 tonnes. The I&C experts took care of the fitting of all measurement points, the linking to the energy supply, as well as of the control systems. To prevent solidification of the bitumen in the pipes, the team installed an electrical trace heating system.

The project also included the safe transport of the plant to the end customer. The packaging and loading of the entire plant, i.e. the partially prefabricated and pre-insulated parts, had to ensure absolutely safe transport with complete protection from damage.

Would you like to know more on the project? Click on Contact and the experts from the plant construction division would be happy to advise you.

The plant construction experts of Kremsmueller fabricated two complete cooling plants for the crude oil byproduct. In this project, too, many competence domains of Kremsmueller meshed with one another: I&C, steel and pipe construction, as well as installation at the end-customer’s site.

Two plants were manufactured, with each weighing between 130 and 140 tonnes. The I&C experts took care of the fitting of all measurement points, the linking to the energy supply, as well as of the control systems. To prevent solidification of the bitumen in the pipes, the team installed an electrical trace heating system.

The project also included the safe transport of the plant to the end customer. The packaging and loading of the entire plant, i.e. the partially prefabricated and pre-insulated parts, had to ensure absolutely safe transport with complete protection from damage.

Would you like to know more on the project? Click on Contact and the experts from the plant construction division would be happy to advise you.